sep . 28, 2024 23:03 Back to list

Chlorothalonil Production Facilities and Their Impact on Agriculture and Environmental Safety

The Role of Chlorothalonil in Agriculture A Closer Look at Factories and Production

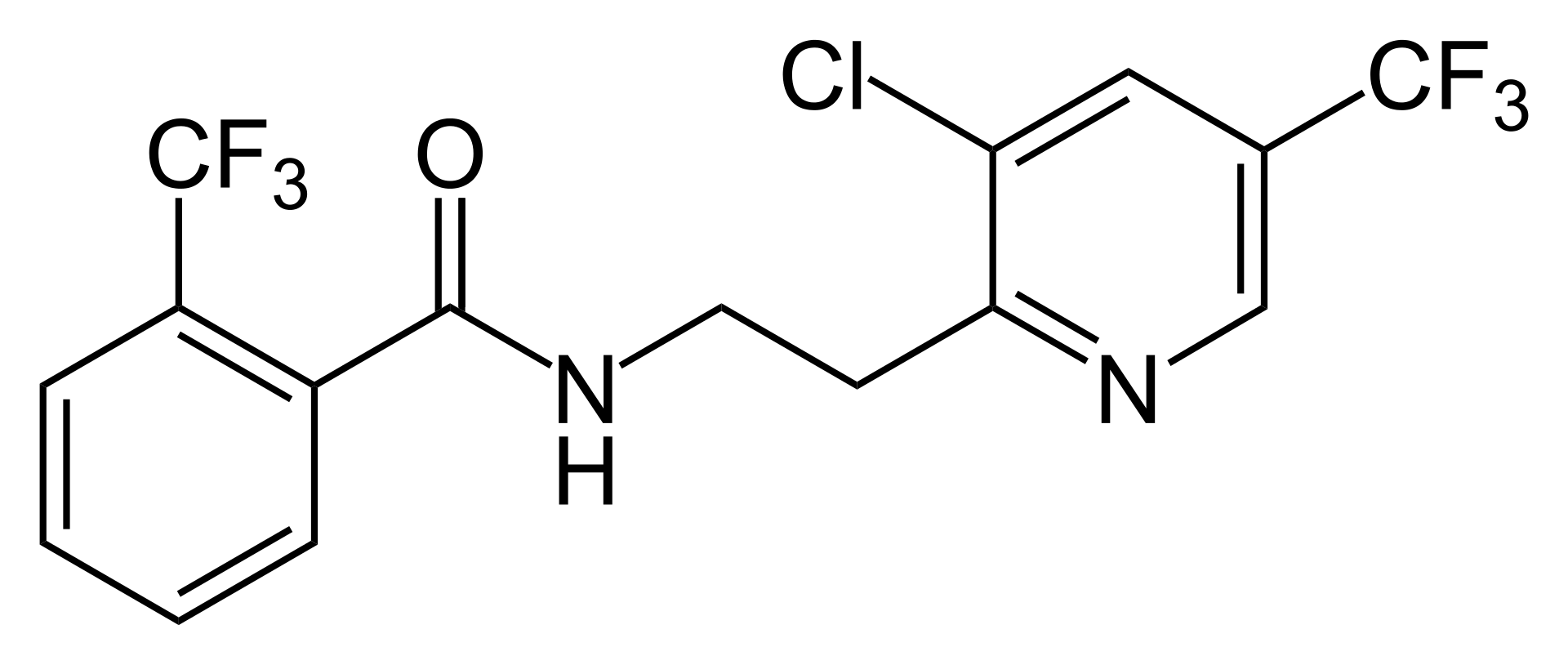

Chlorothalonil, a broad-spectrum fungicide, has been a staple in agricultural practices for decades. This chemical compound, known for its effectiveness against a variety of fungal pathogens, plays a critical role in ensuring crop health and productivity. As the global demand for food continues to rise, the production of chlorothalonil and the factories involved in its manufacturing have become increasingly important. This article explores the significance of chlorothalonil, the processes involved in its production, and the role of factories in meeting the agricultural needs of the modern world.

Chlorothalonil is primarily used to control diseases in crops such as potatoes, tomatoes, peanuts, and turf. Its mechanism of action disrupts cellular processes in fungi, effectively preventing the spread of diseases like blight and rust. The effectiveness of chlorothalonil has made it a preferred choice among farmers, especially those who are looking to protect their yields from devastating fungal infections. However, its use is not without controversy, as concerns over environmental impact and human health persist.

The Role of Chlorothalonil in Agriculture A Closer Look at Factories and Production

The raw materials used in the synthesis of chlorothalonil are sourced from chemical suppliers who provide the necessary precursors. The synthesis process is complex, involving various chemical reactions that require precision and careful monitoring. Factories utilize sophisticated machinery that can handle hazardous materials safely, thereby adhering to stringent safety regulations and environmental standards.

fungicide chlorothalonil factories

Quality control is a critical aspect of the production process. Factories routinely test samples of chlorothalonil to ensure that they meet the required specifications. This involves testing for purity, potency, and the presence of any contaminants. Quality assurance teams are tasked with enforcing strict testing protocols, which not only ensure product efficacy but also promote sustainable practices within the industry.

In recent years, there have been significant advancements in the production technologies used in chlorothalonil manufacturing. Automation and digital monitoring have streamlined many processes, improving overall efficiency and reducing waste. Additionally, factories are increasingly adopting green chemistry principles, exploring alternative methods for synthesis that minimize environmental impact. Such innovations are essential in addressing the growing scrutiny on pesticide use and the push toward more sustainable agricultural practices.

Global regulations also play a significant role in the production and distribution of chlorothalonil. In certain regions, there have been moves to restrict or ban the use of various chemical pesticides due to health concerns. As a result, factories involved in the manufacturing of chlorothalonil must stay abreast of regulatory changes and adapt their practices accordingly. This involves extensive research and development efforts to find safer alternatives or to formulate chlorothalonil in a way that aligns with more stringent guidelines.

In conclusion, chlorothalonil remains a vital tool in modern agriculture, essential for protecting crops from fungal diseases. The factories responsible for its production play a crucial role in ensuring that this fungicide is available to farmers around the world. As the agricultural sector continues to evolve, the production methods and practices in chlorothalonil manufacturing will also need to adapt. By embracing advancements in technology and adhering to environmental regulations, these factories can continue to provide effective solutions for crop protection while promoting sustainability in agriculture. The future of chlorothalonil production will depend on balancing efficacy, safety, and environmental stewardship.

-

Azoxystrobin: Broad-Spectrum Fungicide Solutions

NewsAug.11,2025

-

Best EPA Boscalid: Superior Crop Fungicide for Max Yields

NewsAug.11,2025

-

Best Willowood Imidacloprid: Superior Pest Control Solutions

NewsAug.10,2025

-

Best EPA Boscalid Fungicide: Ultimate Crop Protection

NewsAug.09,2025

-

Cyprodinil Fungicide: Broad-Spectrum Crop Protection

NewsAug.08,2025

-

Tembotrione Herbicide: Advanced 8% OD for Broad Spectrum

NewsAug.07,2025